My Name is Daniel Krätschmer - Simulation Expert and Data Enthusiast - working for Robert Bosch GmbH in several Engineering positions since 2011. In my current position as Senior Manager for Digitalization in Engineering I am serving Bosch setting up our Digitalization Journey in the field of Mechanical Engineering in the Mobility Electronics Business Unit. I am supporting our Bosch Developers for Electronic Control Units (ECUs) and mechatronical systems by:

- Processes: Business Process Digitalization Support

- Organization: Organization Development towards Agile

- Data: Data Management, connected Data and Knowledge Graphs

- Algorithms: Software Development including Simulation Automation and Data Management for several Engineering tasks

- Operations: CAD/PLM Hosting (ptc Windchill & CREO) & Operations for > 1000 Developers worldwide

- Services: Development Environments (IDEs) for Software Developers and Data Scientists but as well Mechanical Engineers.

Source: Daniel Krätschmer

Source: Daniel Krätschmer

Background

In 2001 I started with the Technology Management diploma course at University of Stuttgart deep diving into the disciplines necessary for mechanical engineering and business administration success.

During my studies I combined Engineering competencies of Thermal Turbomachinery as well as Material Science & Strength of Materials to master numerical simulation methods for both fluids and structures.

After my diploma thesis written at DaimlerChrysler and graduation I continued my studies and research at Materialprüfungsanstalt (MPA) Universität Stuttgart focusing on developing complex nonlinear Material Models for e.g., fatigue, damage and fracture mechanics.

In 2009 I took over the responsibility of MPA’s welding lab optimizing spot welding and friction stir welding processes by combined tests and simulation.

In 2011 I obtained a Doctorate Degree (Dr.-Ing.) from the Faculty of Energy-, Process- and Bio-Engieering at Stuttgart University, comparable to an international Ph.D. degree.

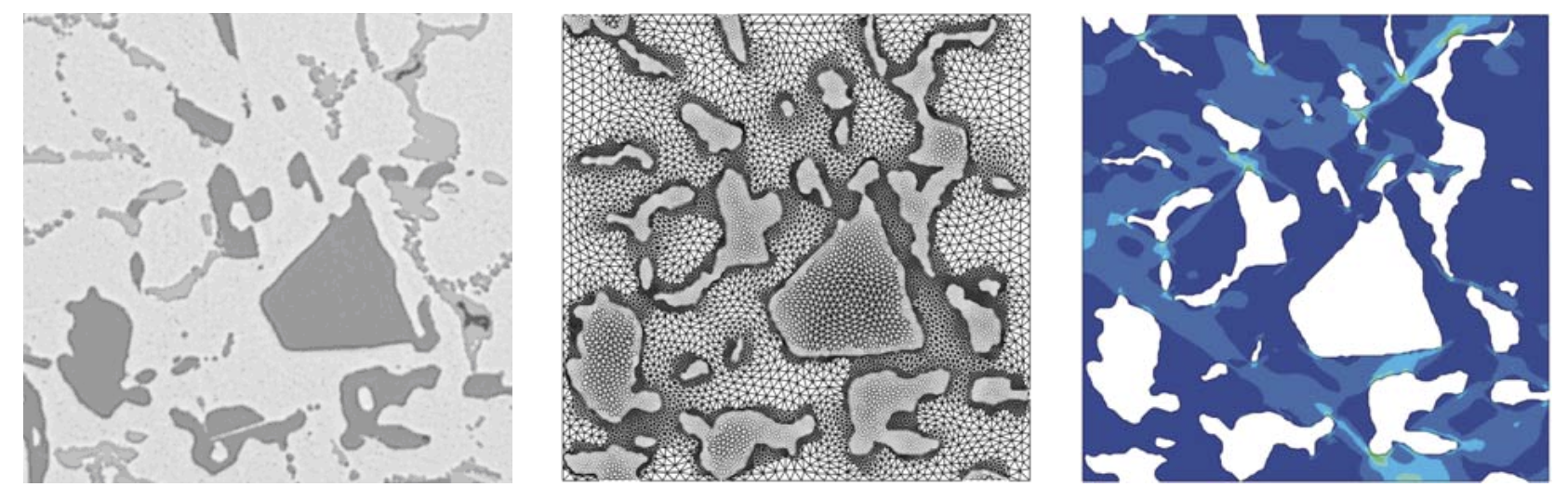

In my thesis Evaluation of microstructural fatigue damage with stochastic methods I analyzed microstructural fatigue of aluminum piston alloys, e.g., AlSi12Cu4MgNi2 and redesigned and extended an existing approach for austenitic steels to calculate damage and remaining lifetime in applying stochastic models based on Markov Chains. Here just an excerpt image of the thesis to illustrate considered microstructure in numerical simulation with constitutive material laws:

Source: Daniel Krätschmer, http://dx.doi.org/10.18419/opus-1923

Source: Daniel Krätschmer, http://dx.doi.org/10.18419/opus-1923